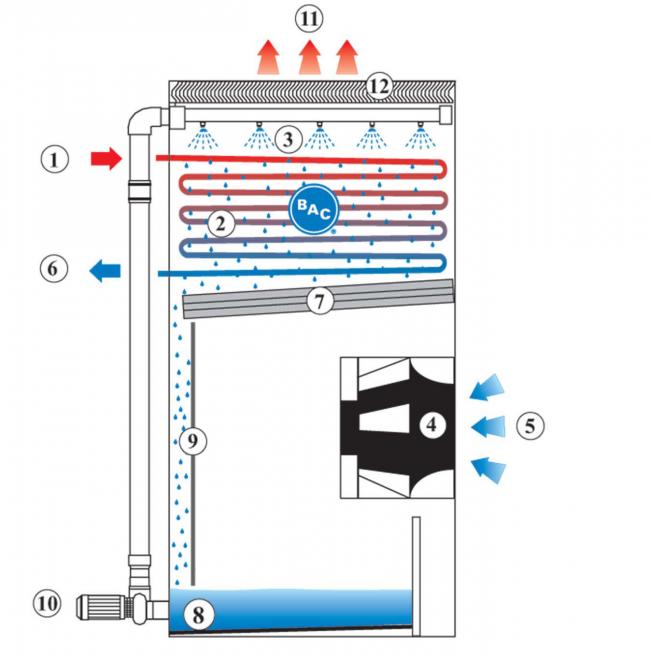

Warm process fluid (1) circulates through an heat exchanger coil (2), which is continuously wetted by the spray system (3) installed at the top of the closed circuit cooler. At the same time the direct driven radial fans (4), located at the bottom of the unit, blow ambient air (5) upwards through the cooler.

During operation, heat is transferred from the process fluid to the spray water, and then to the atmosphere as a portion of the water that evaporates. The cooled process fluid then exits the unit (6). The remaining spray water that falls on the sloping channels (7) continuously flows into the sloping sump (8), where the water is collected. The double blank-off wall (9) guides the spray water into the collection basin, creating a turbulence flow. The spray water pump (10) recirculates the water up to the water spray system. The warm saturated air (11) leaves the cooler through the drift eliminators (12), which remove water droplets from the air.

Interested in the Polairis™ closed circuit cooler? Contact your local BAC representative for more information.