1. Material options

- Heavy-gauge hot-dip galvanized steel is used for unit steel panels and structural elements featuring Baltibond Hybrid Coating.

2. Heat transfer media

- The V-shaped finned coil is constructed of staggered and seamless copper tubes (12 mm diameter) with aluminium, rippled and corrugated fins.

- 2,5 mm fin spacing for optimal air turbulence

- Thick and seamless copper headers and threaded steel connections

- Pressure tested at 15 bar

- Try our option for aggressive environments: special pre-coated anti-corrosion aluminium fins.

3. Air movement system

- Axial fan with exceptionally compact direct drive short integrated motor and fan guard.

- The low profile fan with fan guard features an impeller and motor and is balanced as a complete unit using dynamic single plane balancing. Balance grade is G6.3.

- Fan and motor totally maintenance free, and allow frequent starting.

- Bearings seals and motor encapsulation for long service life.

- The adiabatic units fitted with EC motors (EC in model number) provide an immense reduction in power consumption. The fans are piloted over an RS485 bus system by the controller supplied together with the electrical panel.

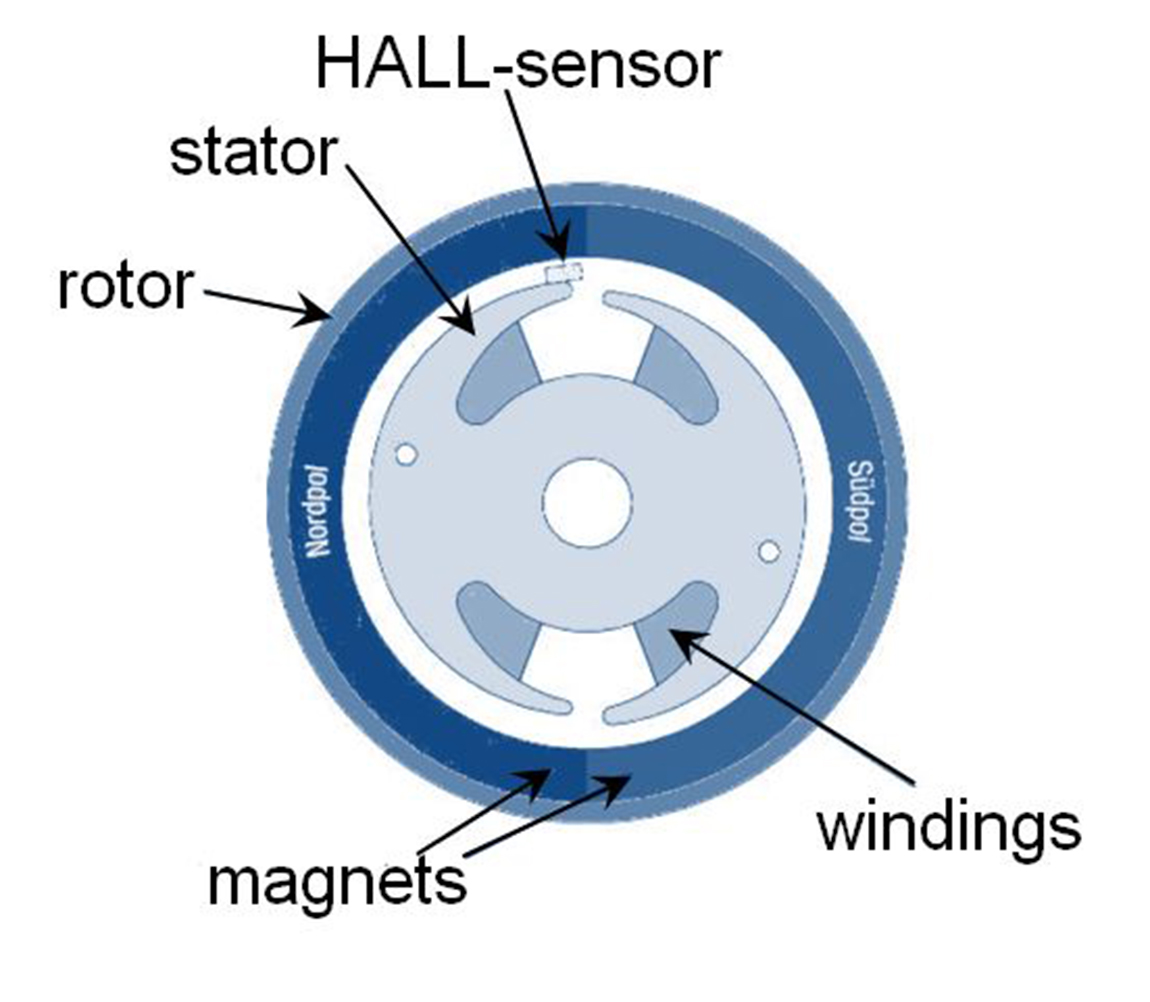

Principle of operation: the magnetic field of the permanent magnets in the outside rotor is used by the consecutively powered windings in the inside stator to let the fan run. The Hall-sensor detects where the magnetic field is strongest, which determines which set of windings will be activated.

4. Water supply on top

The location of the water distribution system at the top of the unit, with pre-cooler pump recirculation system, provides guaranteed back-up. This patented system is designed by BAC and unique in the market. Increasing the redundancy of the unit drastically.

5. Adiabatic pre-cooler

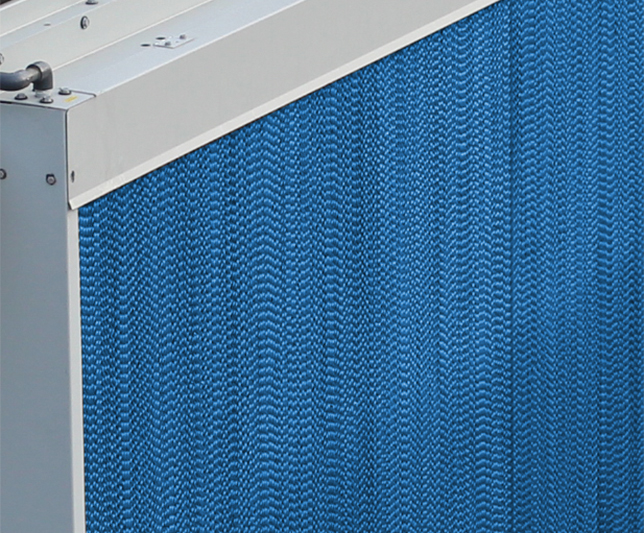

- Evaporative cooling pad of impregnated cellulose with different flute angles encased in bolted heavy gauge stainless steel.

- Distribution pad on top for complete pad wetting.

- Once-through water distribution system, no need for pumps, water drained to sewage.

6. Electrical panel and adiabatic controls

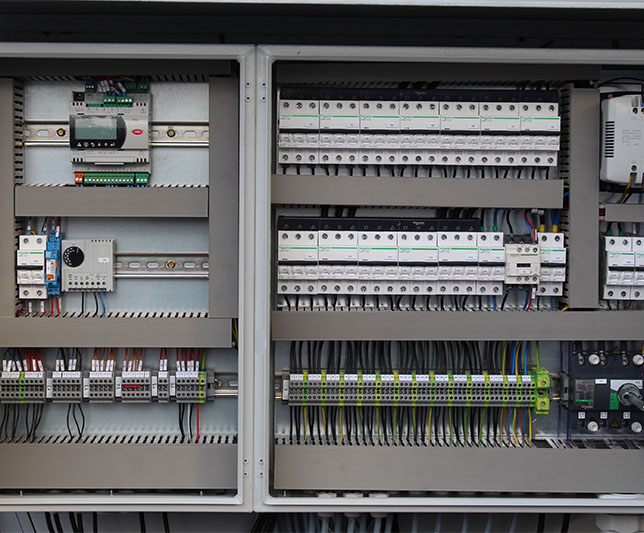

- Fully equipped factory-installed electrical panel with integrated motor controls and adiabatic controls as well as all the required circuit breakers and other auxiliary components.

- Equipped with an internal heater to prevent damage to the internal components inside the electrical panel for ambient temperatures as low as -40°C.

- Intelligent controls featuring the possibility for:

- An additional pre-programmed free cooling set-point

- Day/night operation to limit the maximum fan speed to lower the sound levels

- BMS communication with all common protocols

- Possibility for a master/slave arrangement to further optimize multi-unit installations

- Automatic cleaning cycle rinsing the pads in taxing environments

- Possibility to force unit in dry operation in case water usage is prohibited

Like to know more about the TrilliumSeries Adiabatic Condenser - Model TRC construction details? Contact your local BAC representative.