1. Material options

- Corrosion-resistant materials come as standard for maximum equipment life:

- The unique Baltibond® hybrid coating is standard for all structural components. The hybrid polymer coating is applied pre-assembly to all hot-dip galvanized steel components of the unit.

- The hCore® heat exchanger is made of a highly corrosion-resistant, proprietary stainless steel alloy.

- Optional stainless steel panels and structural elements of type 304L and 316L for extreme applications.

- Or the economical alternative: a water-contact stainless steel cold water basin. Its key components and the basin itself are stainless steel. The rest is protected with the Baltibond® hybrid coating.

2. Heat transfer media

Using a highly corrosion-resistant stainless steel alloy, BAC's patented hCore® Heat Transfer Technology provides unmatched performance, exceptional reliability and long life in an incredibly compact package.

hCore® Heat Transfer Technology

- Proprietary stainless steel alloy exceeds M9540P salt spray environment cyclic corrosion testing at 100 times the typical water chemistry at 82°C.

- Eliminates the need for passivation and the potential for white rust.

- Engineered and manufactured for a 10 bar working pressure.

- Fully-welded with robotic automation for highest quality and maximum reliability.

- Innovative heat transfer surface pattern for maximum wet and dry performance.

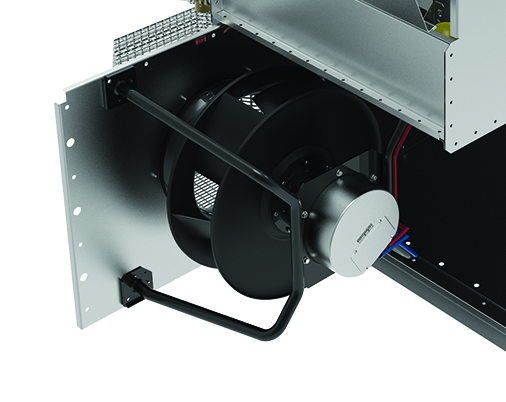

3. Air movement system

- The air movement system of each individual module consists of one or two direct driven radial fans made of aluminium, mounted on EC motors with integrated control electronics. They are completely maintenance free and guarantee redundancy.

- Compact, swing-out design allows easy access and inspection.

- EC motors have a superior efficiency that exceeds the requirements of efficiency class IE4. Integrated electronics of EC motors permit variable speed control for maximum system efficiency, at a significant reduced power consumption compared to AC motors with VFD.

- High external static capacity for indoor applications.

- Energy efficient radial fans give up to 40% savings versus standard centrifugal fans.

- Our drift eliminators come in UV-resistant plastic, which will not rot, decay or decompose and their performance is tested and certified by Eurovent. They are assembled in modules for easy removal from the side.

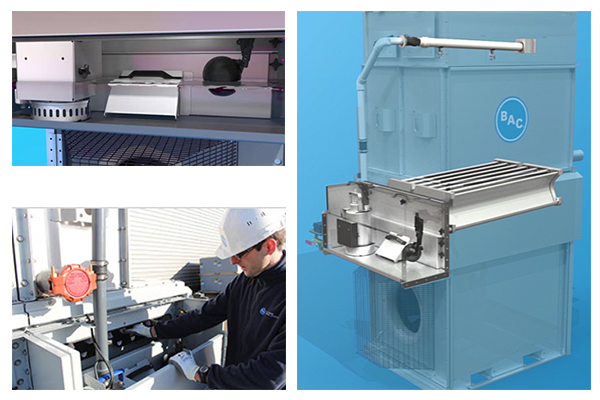

4. Water distribution system

The patent-pending DiamondClear® Design is a water management system without stagnant water inside the unit. This provides continuous self-cleaning, significantly cutting water basin maintenance and water treatment costs by reducing scale build-up and biological growth.

- Patent pending, high performance spray system resists clogging and delivers proper water coverage for reducing scaling. Spray branches have wide, non-clog plastic nozzles secured by rubber grommets. You can easily remove, clean and flush both nozzles and spray branches from outside the unit.

- Sloped spray water collection system diverts water to the compact spray water basin, reducing spray water system volume by 60% and eliminating stagnant water inside.

- Pressurized, turbulent flow of spray water into the compact external basin eliminates the need for sweeper piping and allows inspection during operation.

- Spray water basin has an automated, conductivity-based blowdown system, with a programmable drain cycle that reduces maintenance.

- Fully-enclosed design is protected from sunlight, helping eliminate biological growth.

- Each module has its own SST 304 submersible pump that can be piloted individually to enable a mix of dry and evaporative modules.

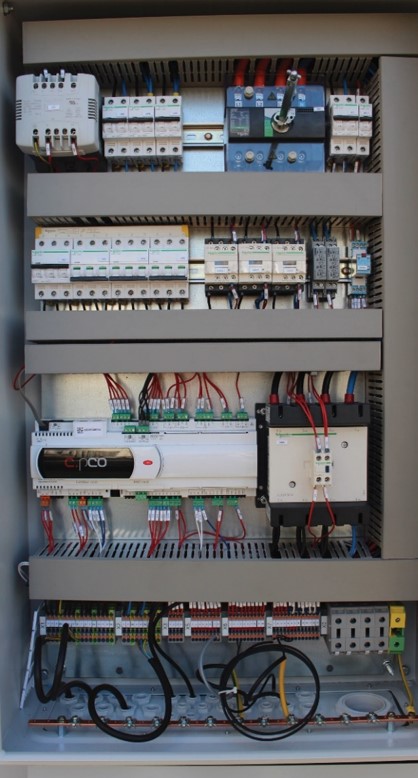

5. iPilot® Control System

BAC innovative iPilot® Control System enables multiple modes of operation to tailor water and energy performance to your needs. The embedded intelligence gives you the ability to effectively balance water and energy savings and achieve the lowest possible operating costs.

- Plug and play, factory set customs controls. All electrical components are pre-wired in the factory to an IP66 electrical panel with Integrated Programmable Logic Controler (PLC) and Human Machine Interface (HMI).

- All site specifc parameters are factory set and tested before the unit is shipped.

- Easy Building Management System (BMS) integration including MODBUS, BACnet and LONWORKS.

- Allowing you to tune your water and energy saving preferences based on your climate, operating conditions and the prices you pay for water and energy.

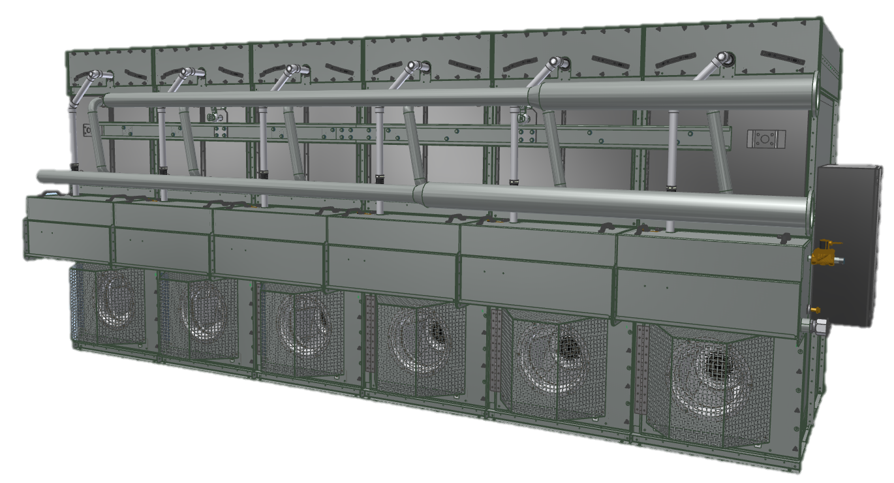

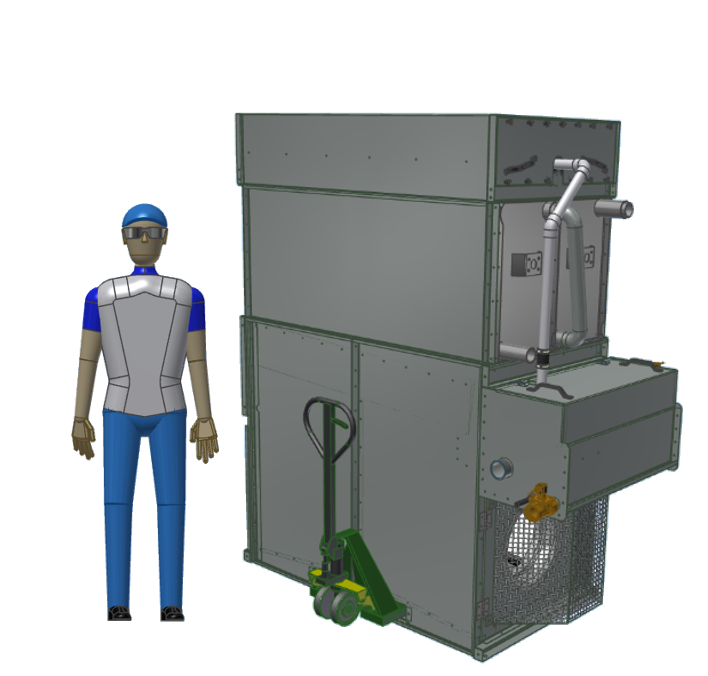

6. Modular Design

The modular design and exclusive iPilot® Control System of the Nexus® enable multiple modes of operation to balance water and energy savings. Its flexible, robust design is ideal for confined layouts and indoor applications. The lightweight, compact modules can easily be maneuvered with a pallet jack and fit into most freight elevators.

- Numerous layout options, up to six modules per unit

- Possibility to ship as completely assembled units or individual modules

- Future expandability by adding modules

- No special rigging equipment required

Need more information? Contact your local BAC representative.