REMARK: Do not use for construction. Refer to factory certified dimensions & weights. This page includes data current at time of publication, which should be reconfirmed at the time of purchase. In the interest of product improvement, specifications, weights and dimensions are subject to change without notice.

General notes

1. Standard refrigerant connection sizes are ND 100 BSP MPT inlet and outlet (for models VXC 14 through 28 refrigerant connection sizes are ND 80 BSP MPT), consult your local BAC representative for size and location. Other connection sizes are available on special order. Refrigerant connections are standard bevelled for welding.

2. Make up, overflow, suction, drain connection and access door can be provided on side opposite to that shown; consult your BAC representative.

3. Unit height is indicative, for precise value refer to certified print.

4. Shipping/operating weights indicated are for units without accessories such as sound attenuators, discharge hoods, etc. Consult factory certified prints to obtain weight additions and the heaviest section to be lifted.

5. The drawing units with only one spray pump show the standard right hand arrangement has the air inlet side on the right when facing the connection end . Left hand can be furnished by special order.

6. Coil, overflow, make-up and spray water connections are always located on the same end of the unit. For double pump units an additional overflow connection will be installed on the other end of the unit.

7. On model VXC 14 through VXC 135 access doors are located at the opposite of the air inlet side, ensure sufficient space for entry when positioning these units.

8. For indoor applications of evaporative condensers, the room may be used as a plenum with ductwork attached to the discharge only. If inlet ductwork is required, an enclosed fan section must be specified; consult your BAC representative for details.

9. Fan kW is at 0 Pa ESP. To operate against external static pressure up to 125 Pa, increase each fan motor one size.

10. Refrigerant charge listed is R717 operating change. To determine operating charge of R 22 refrigerant, multiply by: 1,93. For R134A, multiply by : 1.98.

11. For dry operation, standard motors must be increased one size to avoid motor overloading. Extended surface coils are available to vastly increase dry capacity without motor size increase. Consult your Bac Representative for selection and pricing.

12. Models VXC 357-454, VXC 562-380, VXC 495-516 and VXC 725-804 have only 1 coil casing section and one or two fan motors. Fan cycling results in only on-off operation. On these units all fans need to operate simultaneously.

13. Models VXC 714-907, VXC 1124-1360, VXC 990-1032 and VXC 1430-1608 have 2 coils casing sections and one or two fan motors per coil casing section. Fan cycling results in only-off operation. On these units all fans need to operate simultaneously per coil casing section.

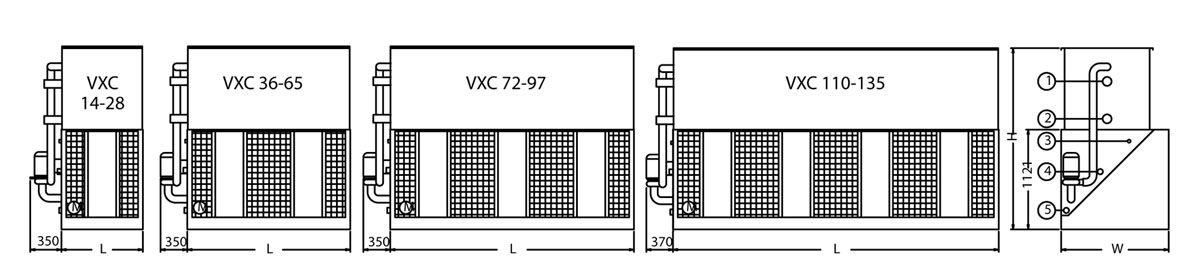

VXC 14-135

1. Refrigerant in ND100 (for VXI 14-28 ND80); 2. Refrigerant out ND100 (for VXI 14-28 ND80); 3. Make up; 4. Overflow; 5. Drain; 6. Access (models 14 thru 135 have access door at the back); For VXC 14 thru 135: make up ND25; overflow ND50; drain ND50.

| Model | Weights (kg) | Dimensions (mm) | Air Flow (m³/s) | Fan Motor (kW) | Water Flow (l/s) | Pump Motor (kW) | R717 charge (kg) | ||||

|---|---|---|---|---|---|---|---|---|---|---|---|

| Oper. Weight (kg) | Ship. Weight(kg) | Heaviest Section (kg) | L | W | H | ||||||

| VXC 14 | 660 | 600 | 580 | 914 | 1207 | 2035 | 2.3 | (1x) 1.5 | 2.2 | (1x) 0.25 | 9.0 |

| VXC 18 | 740 | 670 | 660 | 914 | 1207 | 2245 | 2.2 | (1x) 1.5 | 2.2 | (1x) 0.25 | 11.0 |

| VXC 25 | 830 | 760 | 480 | 914 | 1207 | 2467 | 2.5 | (1x) 2.2 | 2.2 | (1x) 0.25 | 15.0 |

| VXC 28 | 900 | 830 | 540 | 914 | 1207 | 2683 | 2.4 | (1x) 2.2 | 2.2 | (1x) 0.25 | 19.0 |

| VXC 36 | 1050 | 920 | 920 | 1829 | 1207 | 2035 | 4.6 | (1x) 4.0 | 4.7 | (1x) 0.37 | 16.0 |

| VXC 45 | 1170 | 1030 | 1030 | 1829 | 1207 | 2245 | 5.0 | (1x) 4.0 | 4.7 | (1x) 0.37 | 20.0 |

| VXC 52 | 1310 | 1160 | 700 | 1829 | 1207 | 2467 | 4.8 | (1x) 4.0 | 4.7 | (1x) 0.37 | 29.0 |

| VXC 59 | 1330 | 1180 | 700 | 1829 | 1207 | 2467 | 5.3 | (1x) 5.5 | 4.7 | (1x) 0.37 | 29.0 |

| VXC 65 | 1500 | 1330 | 860 | 1829 | 1207 | 2683 | 5.5 | (1x) 5.5 | 4.7 | (1x) 0.37 | 36.0 |

| VXC 72 | 1810 | 1490 | 1000 | 2737 | 1207 | 2578 | 5.8 | (1x) 4.0 | 7.1 | (1x) 0.75 | 41.0 |

| VXC 86 | 1820 | 1500 | 1000 | 2737 | 1207 | 2578 | 7.5 | (1x) 7.5 | 7.1 | (1x) 0.75 | 41.0 |

| VXC 97 | 2080 | 1730 | 1200 | 2737 | 1207 | 2813 | 7.1 | (1x) 7.5 | 7.1 | (1x) 0.75 | 50.0 |

| VXC 110 | 2240 | 1800 | 1200 | 3658 | 1207 | 2578 | 10.4 | (1x) 7.5 | 9.5 | (1x) 0.75 | 59.0 |

| VXC 125 | 2510 | 2050 | 1440 | 3658 | 1207 | 2813 | 9.9 | (1x) 7.5 | 9.5 | (1x) 0.75 | 73.0 |

| VXC 135 | 2540 | 2080 | 1440 | 3658 | 1207 | 2813 | 10.9 | (1x) 11.0 | 9.5 | (1x) 0.75 | 73.0 |